Bionic’s fuel technologies are all centered around the commercial application of advanced microwave technology (bionic µtechnologies) to alternative fuel production processes. We complement proprietary microwave technology with the latest in catalyst development for the hybrid bionic µfuel conversion process.

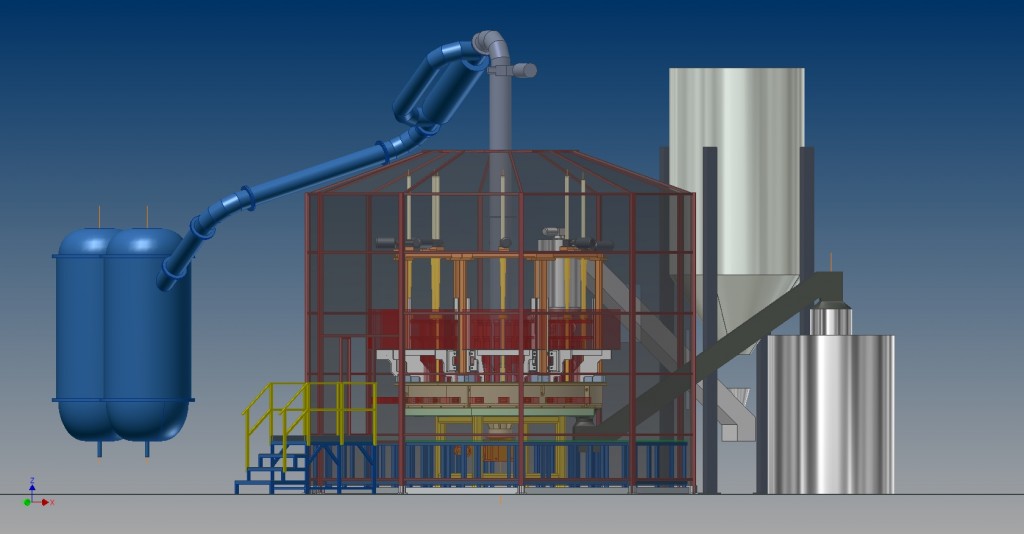

Bionic’s microwave catalytic depolymerization (MWDP) takes pyrolysis to the next level. It stands out as the only microwave driven depolymerization process ready for immediate commercialization. The hybrid combination of microwave and catalytic pathways, activated at comparatively very low temperatures, enhances efficiency and process control. Numerous innovative details have been implemented with this technology for the first time. They cover microwave as well as catalyst application and leave any competition far behind. Due to a unique reactor design supporting the adequate adjustment and fine tuning of reaction conditions as required by each of the various process phases a level of quality in liquid and solid fuel products is achieved like never before.

Bionic’s µfuel MWDP stands out as the flagship activity within the group. With the mf series of energy conversion plants it makes Bionic the global technology leader in the use of microwave applications for alternative fuel production.

Standard applications include biomass to liquid (BTL), waste to liquid (WTL) and “scrap-tires-to-liquid” plants. Also possible are clean and efficient uses in oil extraction from tar sands and oil shale, remediation and oil recovery from oil spills and soil contamination and the processing of tars and ultra heavy waste oils.

Based on its successful MWDP development Bionic proceeded into the field of carbon liquefaction or CTL. Late in 2012 Bionic announced a new microwave assisted coal liquefaction process Bionic µCTL which greatly improves the nearly 100 year old direct Bergius coal liquefaction process. Bionic implemented the process with a new reactor design from the ground up combining microwave radiation with high pressure hydration in a single reaction vessel. Several patent applications are pending on this break-trough technology which has enormous potential as it makes µCTL a clean and energy efficient technology.

This new µCTL process can not only be used to efficiently convert fossil coal into liquid fuels like heavy oil, diesel, gasoline and jet fuel. The process works also with the char fractions produced by pyrolysis techniques from all kinds of carbonaceous feedstock like biomass, municipal and commercial waste streams, used tires and more.

An especially attractive application is the combination of Bionic’s µfuel MWDP process with the new Bionic µCTL technology. A combination which implies a long list of cost saving synergies on both process stages.

Bionic µCTL can also be combined with a coal gasification method called devolatilization producing a quality gaseous fuel product and a coke residue which could then be the feedstock for a second stage Bionic microwave CTL plant. Both methods are making coal a very clean energy to use while at the same time greatly improving energy efficiency.

Let us invite you to visit the Bionic World website where you can learn all about this exiting technology.

You must log in to post a comment.